Use of celluloses and additives in adhesive mortars

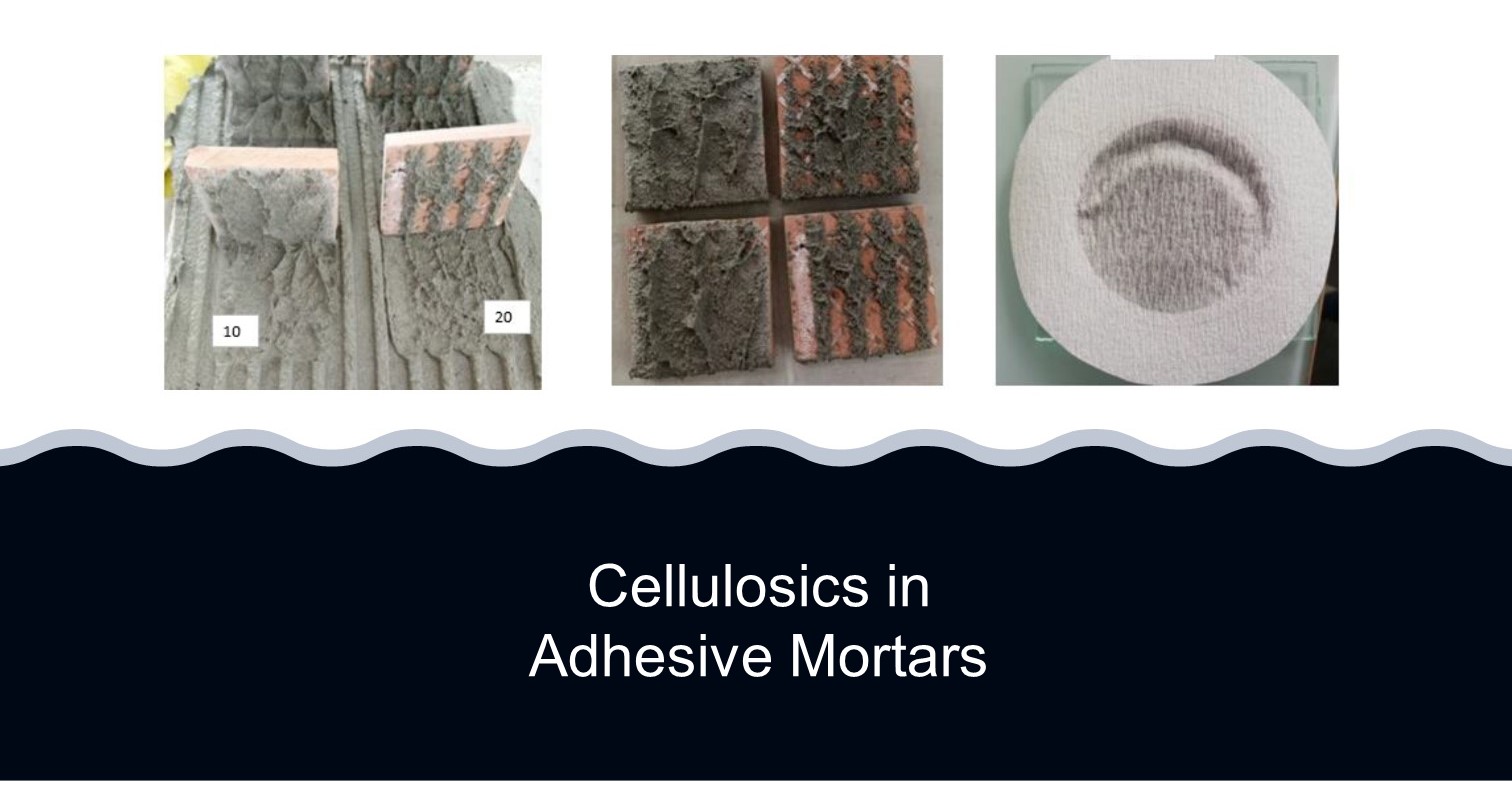

Adhesive mortars, also known as cement-based adhesives, are an input of great importance in the construction sector due to the volume of use and the requirements they must meet. Today, different kinds of additives are used, with cellulose-based rheology modifiers being one of those that play an essential role.

The installation of one square meter of tile can require between 4 and 7 kg of adhesive mortar, depending on the characteristics of the tile, the substrate, and working conditions.

In recent years, these materials have undergone a positive transformation in production technology, which has required raw materials specially designed for particular performances according to the requirements of the different applications.

In the past, the vast majority of tiles of materials such as ceramics, porcelain, marble, granite, terrazzo, and stoneware, among others, were glued with a mixture of cement, aggregates, and water. It was prepared on-site at the time of installation; there was no exact control of proportions or the characteristics of the additions. Today, the issue is different since there are industrial and research and development processes for producing this type of mortar.

The first characteristics widely improved in cement-based adhesives are:

- Open time

- Rheology during installation.

Different rheological and water-retaining additives are used to achieve these properties; however, the main protagonists have been cellulose derivatives.

Celluloses most commonly used in adhesive mortars

The most commonly used celluloses in this application are of the following types:

- HydroxyPropyl Methyl Cellulose (HPMC)

- Hydroxyethyl Methyl Cellulose (HEMC).

Advantages of using celluloses (HPMC and HEMC) in construction adhesives:

- Improve the workability of the adhesive mixture.

- Improve mortar cohesion, resulting in reduced cracking.

- Increased stickiness.

- Decrease vertical sliding, especially important in wall covering.

- Considerable increase in opening time.

The opening time represents the maximum time that can elapse from the spreading of the adhesive on the substrate to its covering with the tile to achieve the minimum adhesion required.

Complementary additives to celluloses used in adhesive mortars

In general, the use of other additives will depend on the characteristics to be conferred to the adhesive and the minimum requirements to which the adhesive must be subjected according to the classification within the standards or regulatory norms in each region. Many options complement the action of cellulose, but the most important ones to improve the rheological properties requirements of adhesive mortars are:

- Cellulose fibers.

- Starches

- Clays.

Quality standards related to mortar requirements

The ISO 13007 and ANSI A118 series of standards are the most widely used to validate the quality and possible use of adhesive mortars in particular applications.

At Mathiesen, we know the technical requirements that these standards demand; we understand the reality of each region, and we have a wide portfolio of raw materials to improve the quality and competitiveness of the different types of mortars.

Contact us to learn more about our portfolio of construction products and request support from our technicians; we will gladly guide you if you need help to meet the requirements of your formulation.