Clarification as part of water treatment

COAGULATION AND FLOCCULATION AS PART OF THE WATER TREATMENT PROCESS

In ancient times, water treatment would focus on improving its appearance by using methods such as carbon filtration, exposure to sunlight, boiling it and sieving it. The first few chemical treatments date back to ancient Egypt (1,500 B.C.) when it was found that alum would cause suspended particles to sediment. It wasn’t until the late 19th century that it was discovered that turbidity was not merely an aesthetical problem. As a result, the design of water treatment systems focused on reducing turbidity, thereby removing microbes.

Despite all the advances and technologies that were developed in the field of water treatment, the removal of suspended solids, turbidity and various contaminants using chemicals is still one of the main tools available for a number of purposes such as drinking water purification, wastewater treatment and sludge thickening, among others.

The chemicals used in these operations may be generally classified into coagulants and flocculants. The former have the purpose of facilitating the grouping of colloidal particles that do not sediment quickly due to their size, while the purpose of the latter is to enmesh or bind larger particles or groups of previously-destabilized colloidal particles to easily remove them from the water.

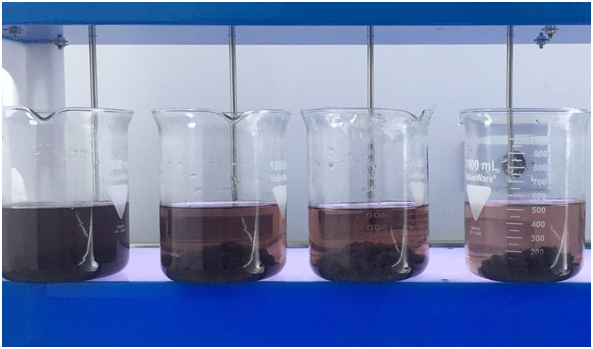

The coagulation and flocculation processes may be performed either independently or combined as part of the clarification process. The success of the coagulation, flocculation or clarification processes depends on factors that are inherent to the plant’s design, such as contact time, flow speed and the correct selection of chemical products.

Coagulants and Flocculants:

Among coagulants, iron and aluminum inorganic salts see the most use. Inorganic coagulants generally offer lower per-kilogram costs, are widely available and, if correctly applied, are efficient in removing suspended solids. Additionally, they enable the removal of organic compounds in the water, which can then be combined with chlorine during the disinfection phase.

Aluminum sulfate, ferric sulfate and ferric chloride reduce the pH, which is why aluminum chlorohydrate (ACH) and inorganic polymers are seeing increasing use. Additionally, we have organic coagulants, which can be used to promote coagulation. Anionic promoters are generally used with metallic coagulants, and low and intermediate molecular mass cationic promoters can be used by themselves or in combination with ferric coagulants to attract suspended solids and neutralize their charges.

Manufacturers can offer a wide range of polymers tailored to the quality of the water, controlling the level and type of charge, and the molecular mass. Polymers work in broader pH ranges than those of inorganic coagulants. And they can be used in low doses, generating lower volumes of higher density sludge that sediments faster.

While organic coagulants are many times as expensive as inorganic ones by weight, their use can reduce the overall cost of treatment per cubic meter of water.

Among flocculants we can find linear or branched organic polymers – mainly polyacrylamides (PAM) – of different molecular weights, with different levels of positive (cationic), negative (anionic) and neutral (nonionic) charges.

The choice and dosage of a flocculant will depend on the concentration of solids in colloidal state or suspended matter, as well as their nature, water salinity and pH. And even though a few practical guides exist for their selection, it is necessary to perform treatability tests to confirm which the product that is most suitable for the application is, and the recommended dosage.

Flocculants can be used in multiple applications such as drinking water purification, industrial wastewater treatment, in sludge thickening for dehydration, stabilization of drilling mud, sugar clarification and paper manufacture, among others.

For the correct use of these products it is recommended to seek the advice of companies that have the experience and know-how to provide technical support, adequately analyzing the application, the opportunities for improvement and the treatment process, in order to guarantee low costs and the attainment of the required water quality.